ABOUT US

Breakthrough

INTRODUCTION

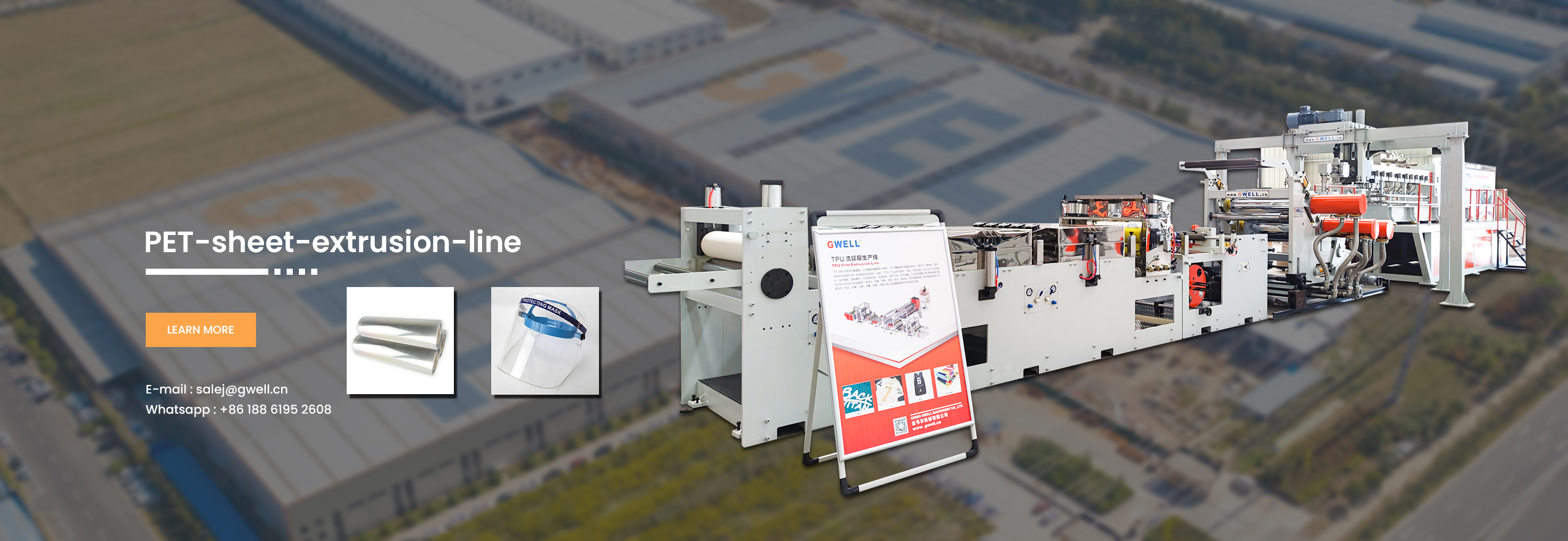

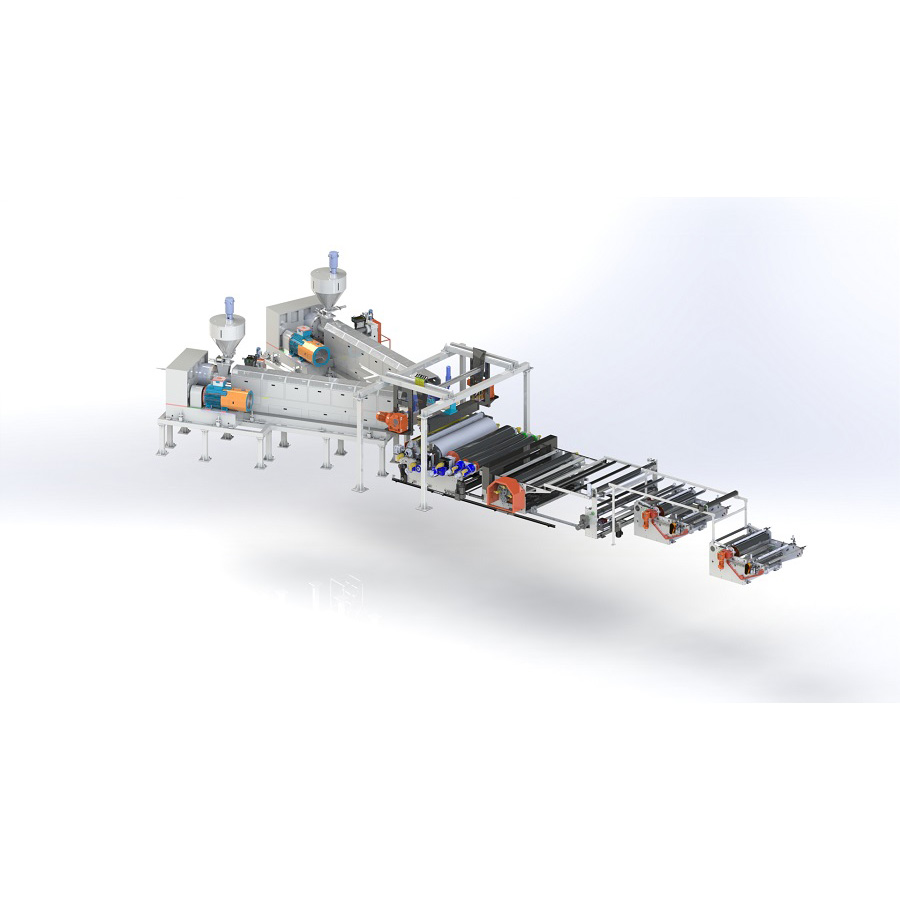

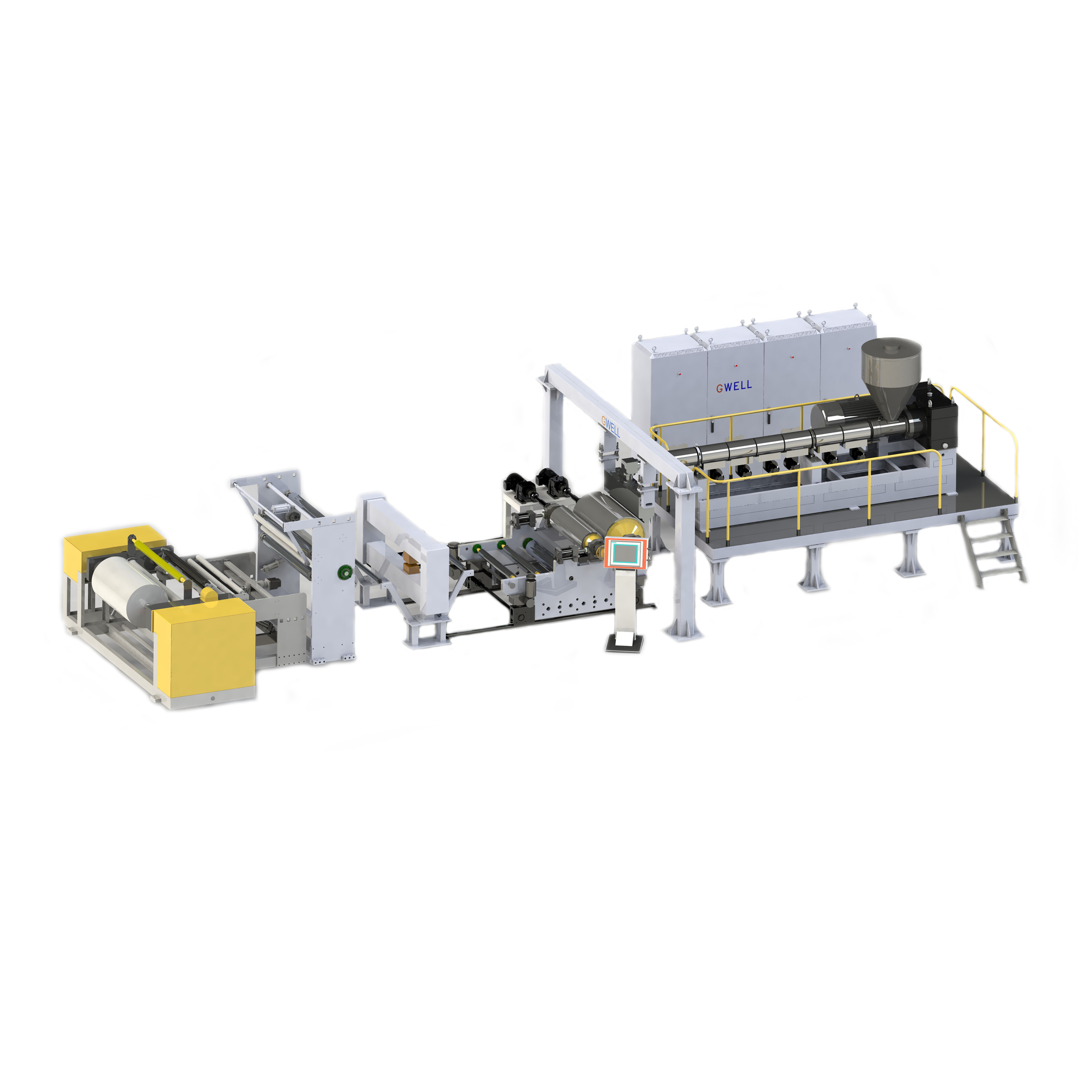

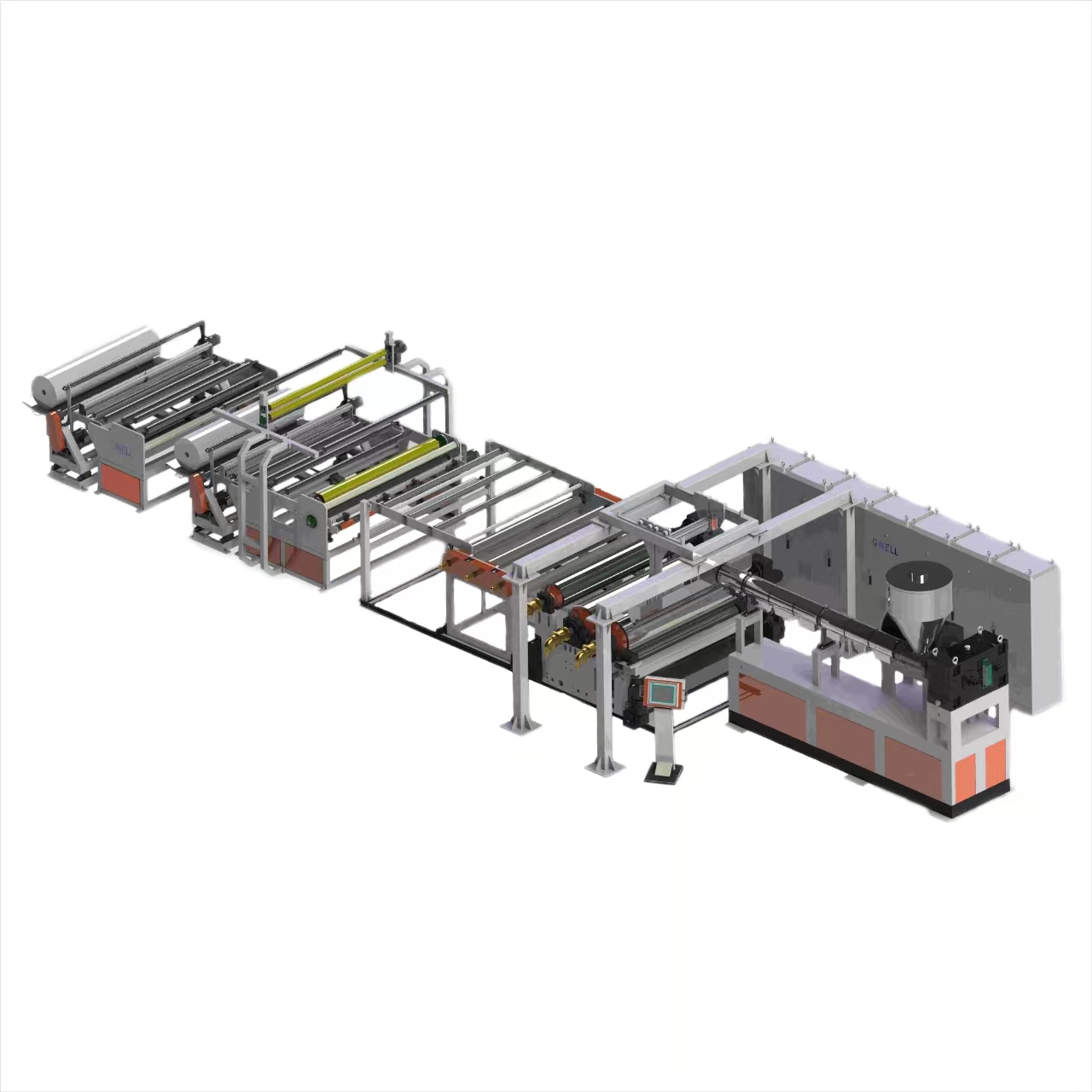

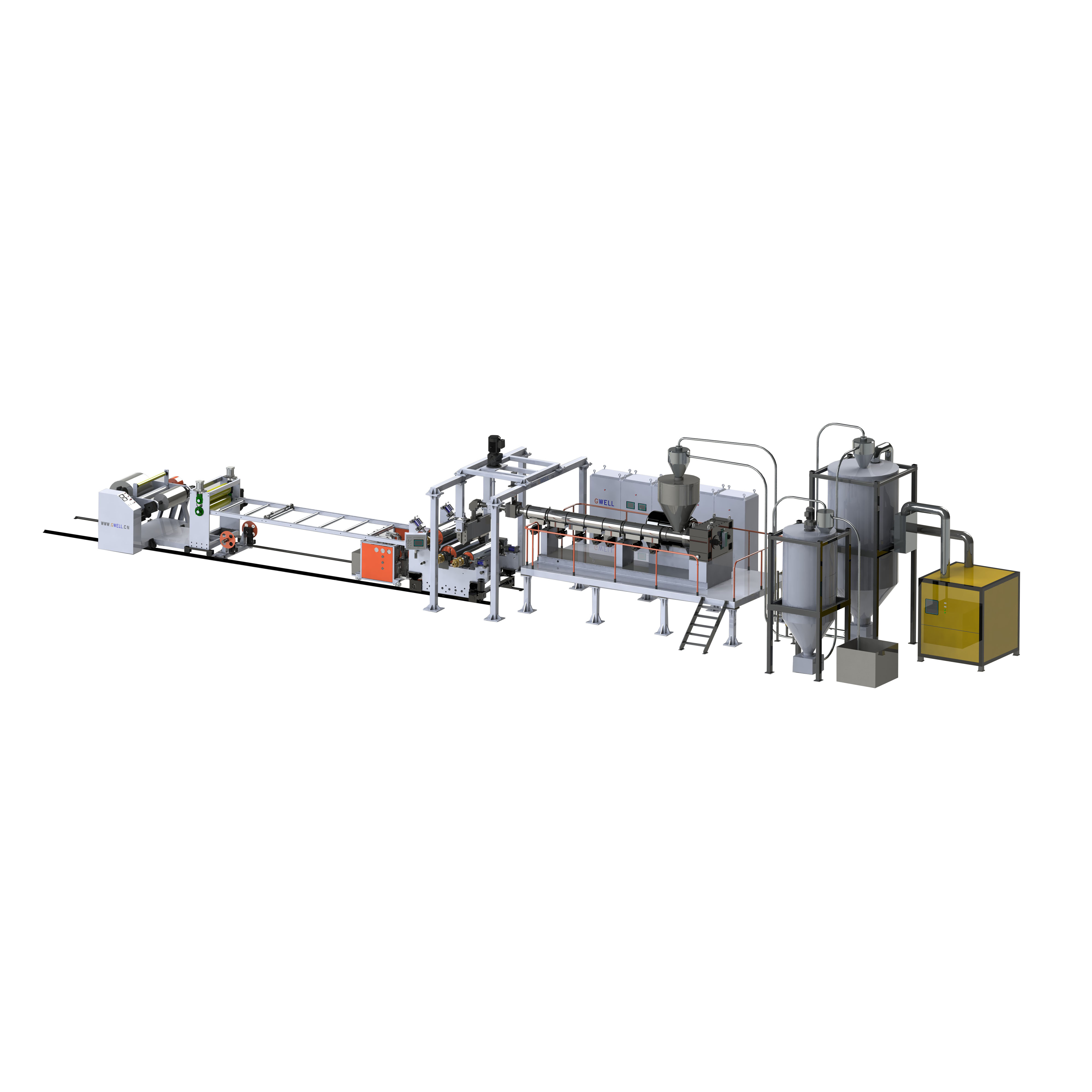

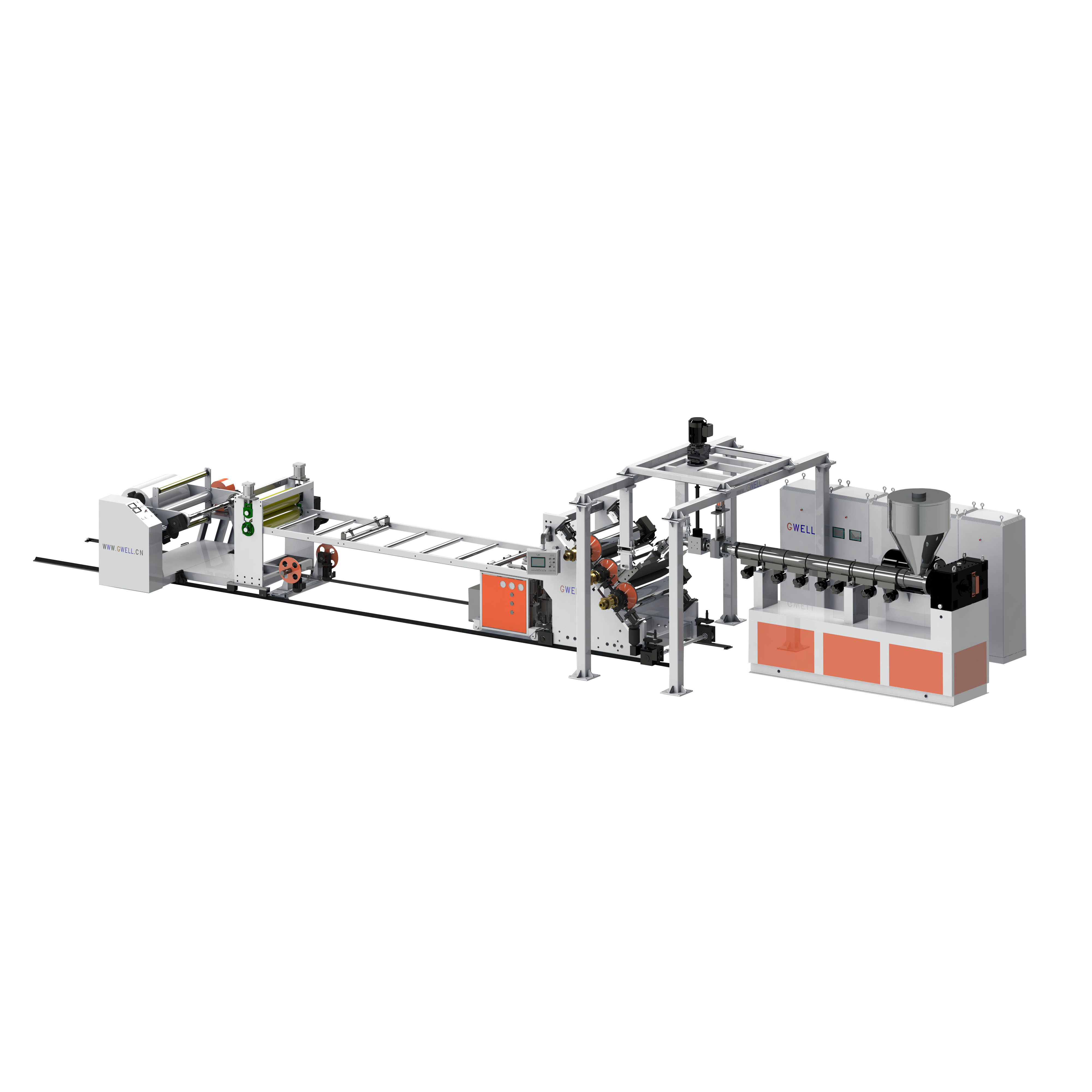

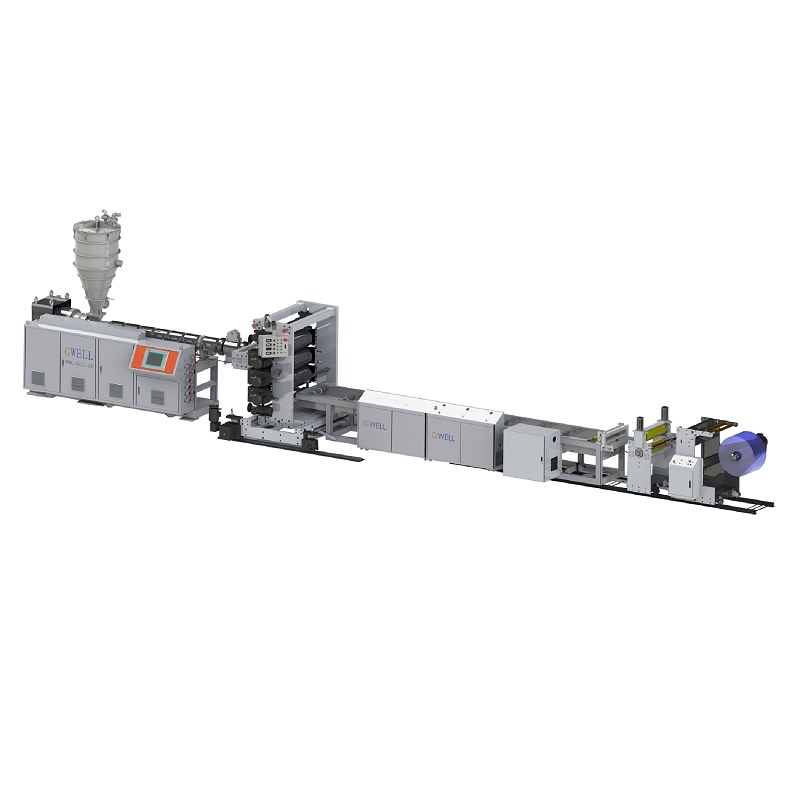

CHINA GWELL is a high-tech enterprise, committed to providing customers with plastic sheet, board, film and other extrusion lines. GWELL can provide Turn-key projects, such as stone paper project, EVA solar film project, PP building formwork equipment, CPP cast film project, etc.

GWELL has a strong technical equipment strength and key capacity, committed to high-end product development, international market development. “Realize customers’ value” is the company’s long-term business philosophy.

-

-Shanghai

-

-Suzhou

-

-YanCheng

-

-NanTong

products

Innovation

NEWS

Service First

-

Advantages Of Plastic Hollow Grid Board

1. Significant environmental protection effect Hollow boards have the characteristics of being non-toxic and pollution-free, with simple waste disposal and no pollution to the environment. It can also be reused as waste and made into other plastic products. 2. Lightweight and material saving Holl...

-

Excellent Performance And Diverse Application Scenarios Of PC Tiles

In the building materials market, traditional building materials such as color steel plates and asbestos tiles have long dominated. However, their shortcomings are gradually being exposed. Color steel plates have poor weather resistance and generally exhibit obvious rusting and corrosion after 5-...