The sunlight board is mainly made of PC/PET/PMMA/PP material, ABS plus PC material, and FRP resin. In English, it is polycarbonate hollow sheet or pet sheet or pmma sheet or pp sheet. The term sunlight board is a common name for polycarbonate hollow board in China, and is generally not used to refer to other hollow boards. Corresponding to its sibling product, polycarbonate endurance board, in terms of physical properties, endurance board is solid board, and sunlight board is hollow board

To a certain extent, it can replace glass and plexiglass as the best building materials. Polycarbonate sheet has the advantages of high light transmittance, high resistance strength, light weight, good sound insulation, strong weather resistance, good flame retardancy, and ultraviolet resistance. It is a kind of high-tech, excellent comprehensive performance, energy-saving and environmentally friendly plastic plate.

Its light transmittance can be as high as 91% or more, impact resistance, impact resistance is very good, the anti-riot shield is also made of the same kind of raw materials, high light transmittance and anti-smashing characteristics make it have the title of “unbroken glass”.

2. Product specifications and classification

Product Category

The main categories of polycarbonate sheet (PC board) are pc sunlight board, PC endurance board, PC wave tile, PC lighting tile, and PC synthetic resin tile.

The thickness of polycarbonate board is generally 0.8cm, 1.0cm, 1.2cm, 1.5cm, 2.0cm, 2.5cm, 3.0cm-30cm.

Different product forms can be divided into solid and hollow.

Solid board: Usually called endurance board, it is a solid single-layer structure, with a conventional thickness of 1.8-20mm.

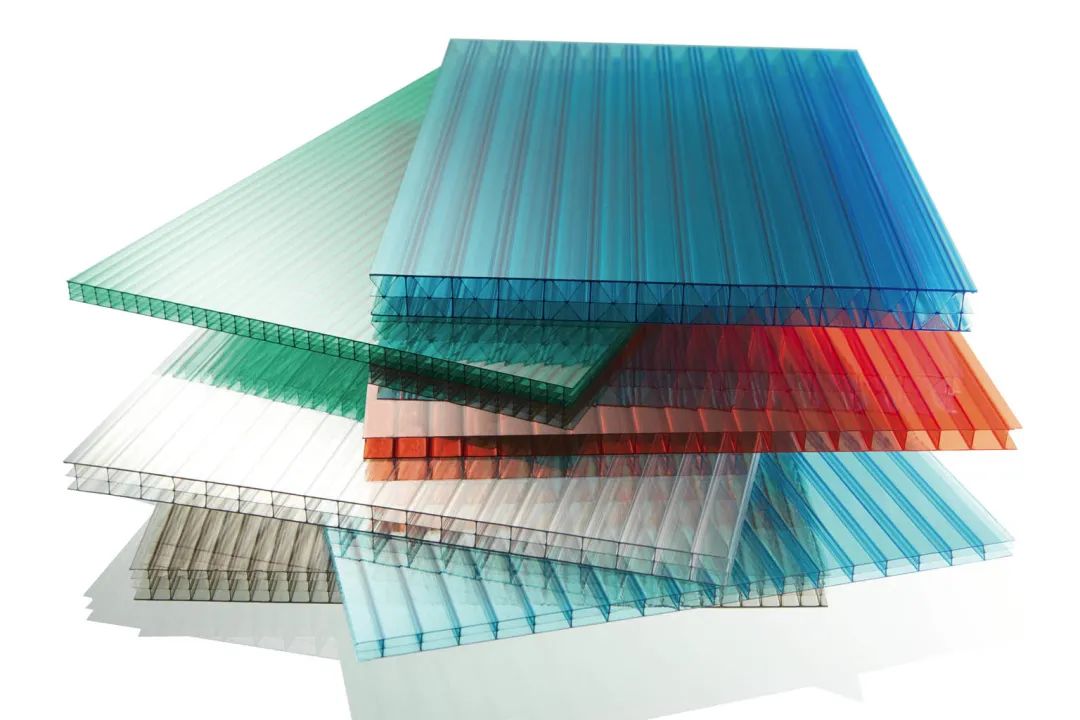

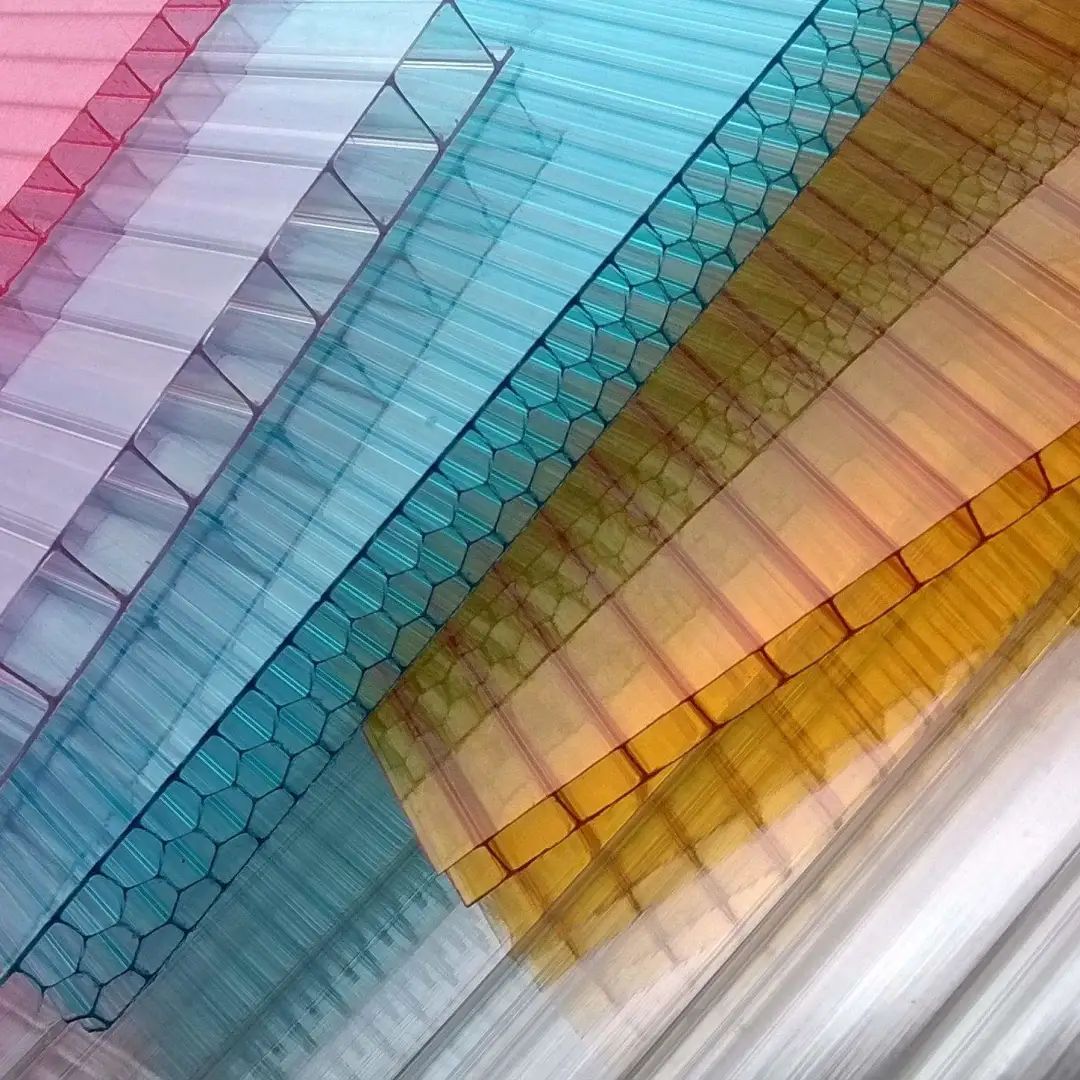

Hollow core board: Usually called sunlight board, it is a multi-layer hollow structure, and the commonly used structures include rice hollow board, double-layer, three-layer, four-layer grid hollow board and honeycomb hollow board.

PC wavy tile, PC lighting tile, PC synthetic resin tile: in fact, it is made into a tile-shaped endurance board.

The appropriate structural plate can be selected according to the different parts and functional requirements.

Post time: Mar-01-2024