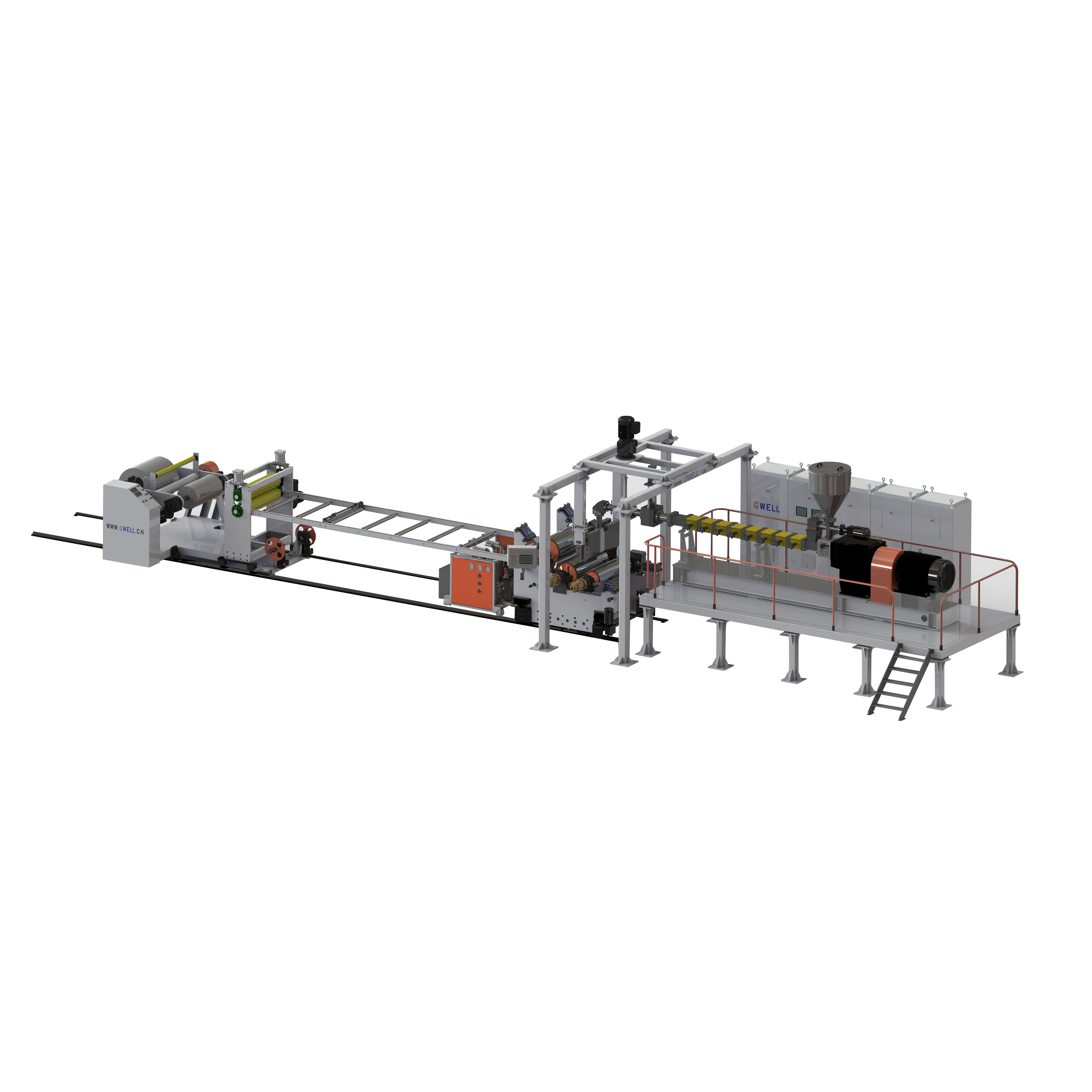

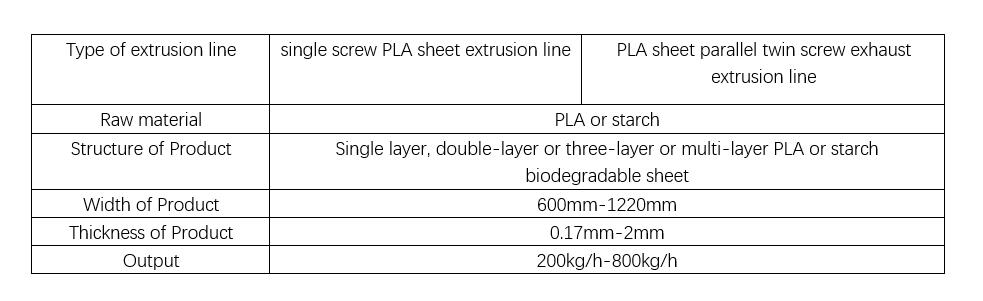

PLA sheet extrusion line

Parameter

Single screw production line for PET sheet

single screw extrusion production line for APET, PETG and CPET sheet is the most mature project with the most stable production at present. Generally, single extruder production line or twin-extruder production line is adopted and Gwell uses the latest technology to increase the general efficiency by 30%.

PET sheet single screw exhaust production line

this machine only needs to crystallize PET, and does not need to dry. Its advantages: low energy consumption, simple process, convenient equipment maintenance, and can ensure the blister 18CM deep cup.

The PET sheet twin-screw exhaust line (free from dry and crystallization)

Gwell launched PET sheet twin-screw exhaust line without drying and crystallization which has the advantages of low energy consumption, high efficiency.This machine is Gwell's continuous improvement upgraded products , and its central vacuum system has been upgraded. The original roots - water ring pump group upgrades to roots - rotary vane pump, which can make the vacuum degree reach 10 pa, or less. Meanwhile by using PET special alloy steel thin-wall roller unit can increase the cooling efficiency, so as to increase output, improve product toughness and transparency. Gwell's independently programmed operating system ensures that the device is user-friendly and easy to operate.

PET sheet planetary multi-screw exhaust production line (free from crystallization and drying)

the planetary screw extruder is adopted as the main machine to increase the space for materials and air, and with the vacuum pumping system newly developed by Gwell can meet the needs of customers with large output and high quality sheets.

Case Presentation

Partner