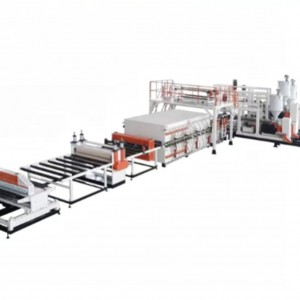

Polyurethane glass-fibre composite solar frame pultrusion line

GWELL combines advanced pultrusion technology at home and abroad to independently develop and launch hydraulic type pultrusion production lines and caterpillar type pultrusion production lines.It uses well-known domestic and foreign brand components to provide customers with stable and reliable quality,easy operation,and highly efficient double outputs PV special frame production line.

Compared with traditional aluminium and metal PV frames, polyurethane PV frames have the following advantages:

1.Polyurethane a strong resistance to salt spray and chemical corrosion.

2.Polyurethane composite material has excellent mechanical properties, its axial tensile strength reaches more than 7 times of the traditional aluminium alloy material.

3.Polyurethane border can also be used in conjunction with water-based polyurethane coating, greatly increasing the weather resistance of the border, and very low VOC emissions.

4.PU frame has a high volume resistivity, photovoltaic modules encapsulated with polyurethane bezel greatly reduces the possibility of forming leakage circuits, which helps to reduce the generation of PID potential-induced attenuation phenomenon. The power generation efficiency of the panel is improved.

Equipment features:

1. Traction force touch screen display;

2. Stepless adjustment of traction speed;

3. With automatic alarm for oil temperature and oil filter blockage;

4. Hydraulic cylinder seals are imported, and the power output of the pump unit is stable;

5. The main electrical and hydraulic components adopt international famous brand, high sensitivity and low failure rate;

6. Pneumatic up and down cutting, pneumatic compression, pneumatic tracking, cutting saw blade is toothless saw blade;

7. Interactive HMI touch screen control, pultrusion speed, temperature, clamping force are displayed and controlled in the touch screen.

Provide service:

1. Send 1-2 technicians to the customised party to guide the installation and debugging of the equipment.

2. The customised party will provide its own auxiliary facilities according to the foundation installation plan provided by the contracted party, and do the preliminary preparatory work for the equipment installation; the water, electricity and gas lines will be laid in the designated position according to the requirements of the installation plan, and all materials required for the production will be prepared.