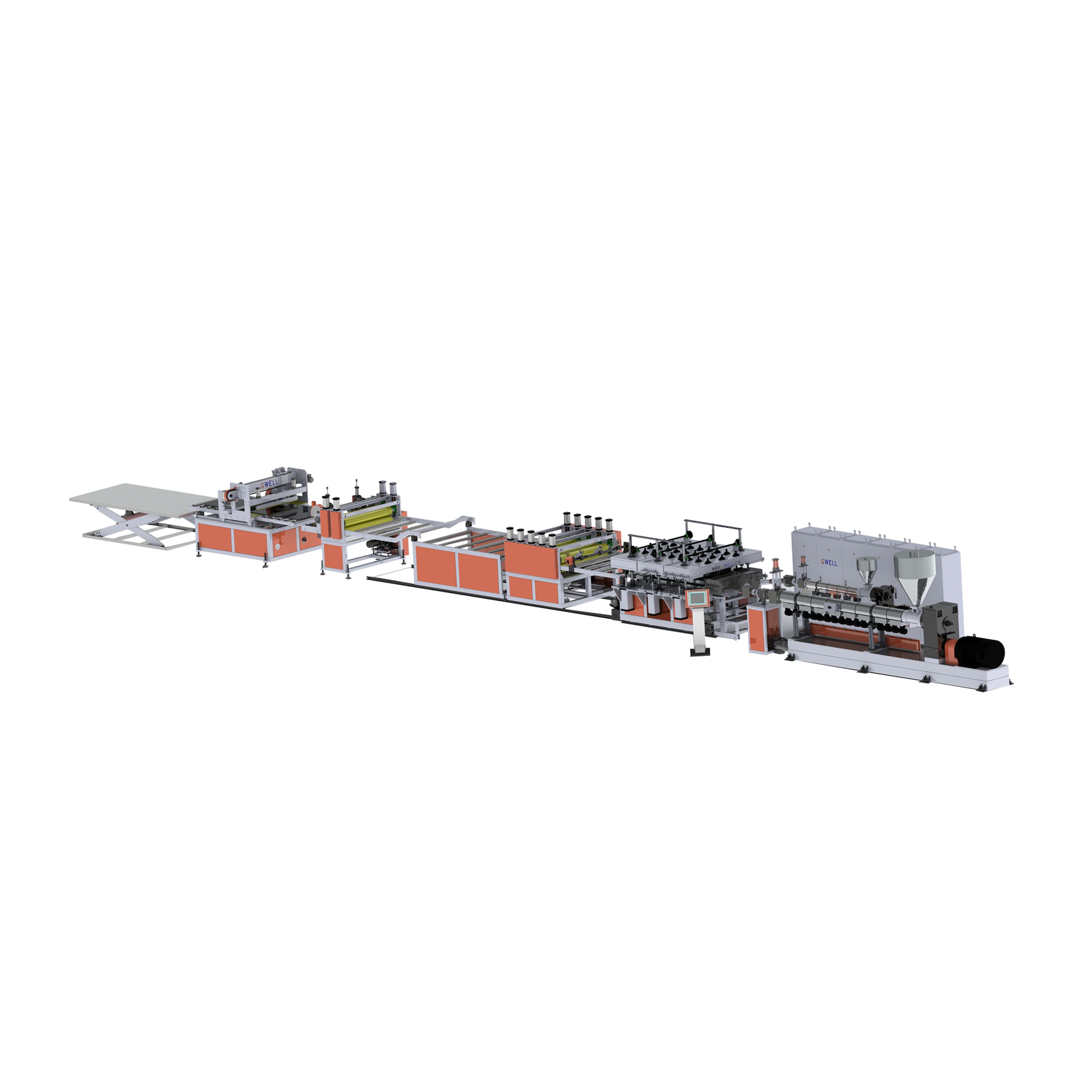

PP Construction Formwork Extrusion Line

GWELL company is dedicated in manufacturing PP hollow construction formwork extrusion line. GWELL absorbs the domestic advanced extrusion technology and own innovation and successful develop this PP hollow construction template extrusion line. This line is compoesd of two single screw extruders (or one single screw extruder and one parallel twin-screw extruder) and hydraulic screen exchanger, mould, calibration machine, one time tractor, annealing furnace, cooling box, secondary tractor, cross-cutting machine and conveyor. We provide a full set of production equipment for domestic and foreign companies. The structure of this template has changed from the original O hollow structure, to 米 type, V type, N type, 井 type, and finally fixed to 井 type. It has been accepted by the market in terms of the amount of materials and structural properties. Its products have many advantages, such as smooth surface, small size error, nailable, planed, corrosion-resistant, flame-retardant, etc. Compared with the traditional template, the construction template has the following characteristics:

1. Good heat retaining property, conducive to shorten the construction period.

2. High support strength, not easy to deformation, impact resistance, wear resistance.

3. Cement is not easy to stick on it. The template is easy to demoulding after construction.

4. Plastic formwork can be processed, planing, sawing, nail, and wood formwork can be used at the same time;

5. The surface of the plastic template is smooth, no need to brush release agent, so it reduces the cleaning, maintenance costs.

6. Light weight, high efficiency, easy to open and dismantle mold, low labor intensity of handling operation, high construction efficiency.

7. Adopt the way of processing wood to process the plastic template. The template also can be welded, so it can be flexible to do secondary processing in the construction site.

8. Long life, many repeated use times. Finally, the damaged plastic template can be crushed again and reprocessed into a new template, saving resources and meeting the requirements of “green industry”.

9. Low cost, long service life, turnover times can reach more than 100 times. And the used waste board, scrap material can be recycled, which saves cost and reduces pollution. The general use cost can save over 30% than the traditional wood template.

10. Good water resistance. Even if it is completely immersed in water for several days, it will not be deformed by moisture. Acid and alkali resistant, corrosion resistant, not rot and rust, especially suitable for basement engineering, highway and railway bridge piers and other damp environment.

11. Save the process, and improve the construction efficiency. PP hollow plastic construction template’s two surfaces (smooth surface or decorative surface) have different effects. For example, after the removal of the formwork by using smooth surface, the wall’s surface will be smooth. There will be no need for secondary plastering, saving materials and time, reducing the cleaning and maintenance costs, and the quality of concrete after molding will be stable. If using decorative pattern, it is advantageous to combine with plastering layer. In particular, the decorative pattern used on bridge piers meets the requirements of decorative surface and decorative water, and because the decorative pattern has a special light diffuse reflection effect, avoiding strong light reflection to affect the driver’s line of sight, which plays a role of safety protection.

In a word, plastic formwork has more characteristics than conventional building formwork. Plastic formwork will become the ideal product for the construction of the 21st century to replace wood, steel and bamboo with plastic formwork.

Products are widely used in:

Transportation: ship, plane, bus, train car, ceiling, car core layer, interior decoration.

Advertising: screen printing, computer lettering, advertising signs, boards, signs board.

Other Uses: formwork, sports equipment, breeding materials, waterfront moisture-proof facilities, water resistant materials, art materials all kinds of portable partition.

Industrial application: chemical industry anti-corrosion engineering, heat forming parts, cold storage board, special cold protection engineering, environmental protection board.

Construction, decoration industry: building exterior wall board, interior decoration board, residence, office, public building space, commercial decoration rack, dust-free room board, ceiling board, kitchen utensils, sanitaryware.