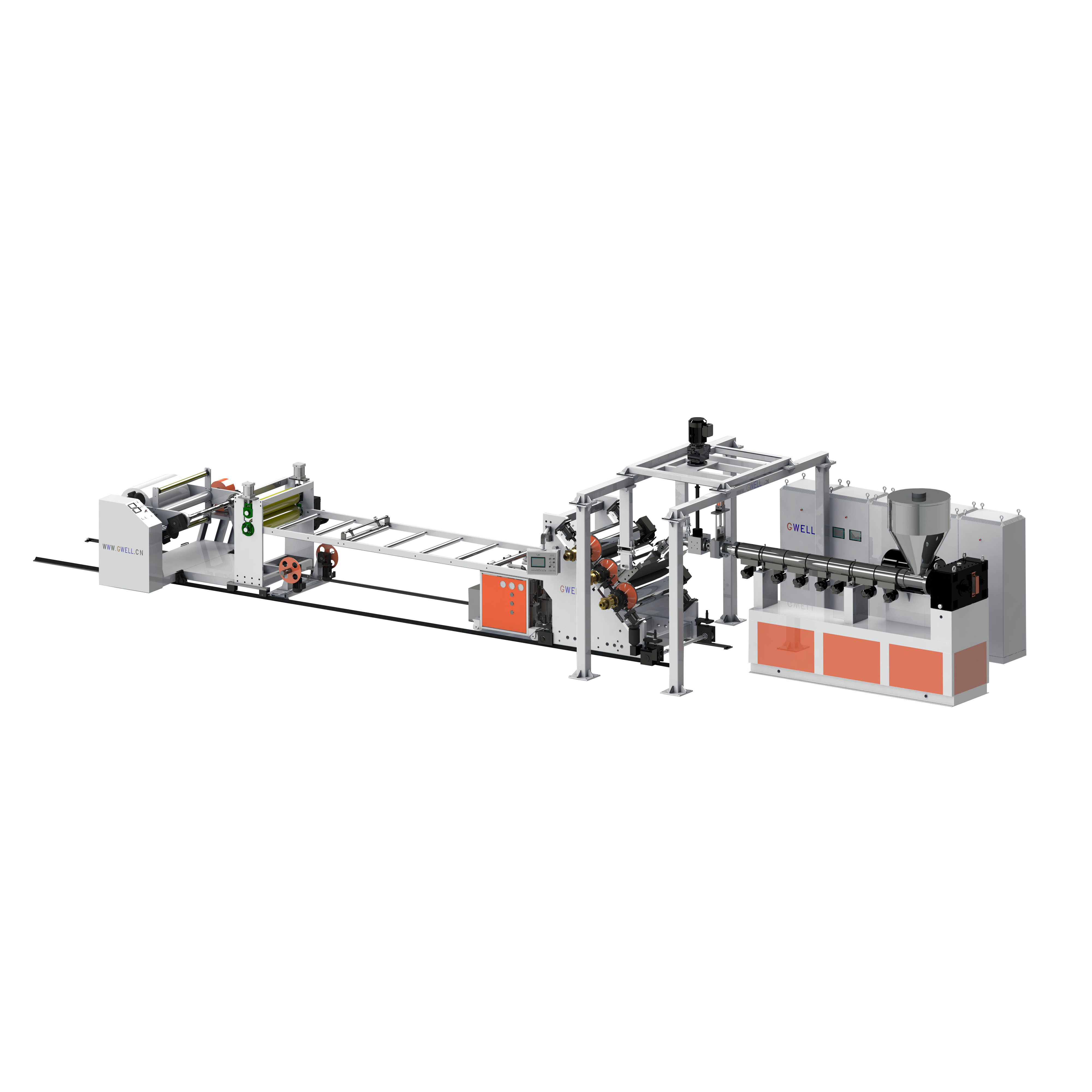

PP PS sheet extrusion line

Machine Video

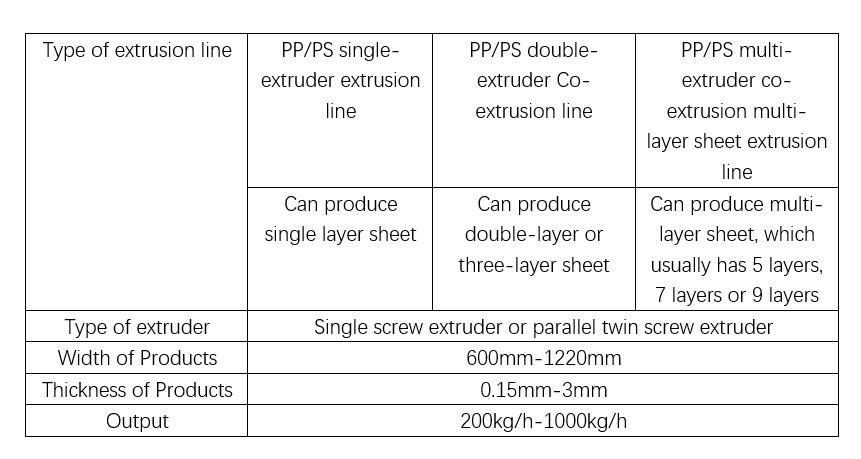

Parameter

Gwell PP/PS sheet production line

The common PP/PS sheet extrusion production lines are single extruder which produces single-layer sheet, double extruders which produce three-layer sheet. There are also multiple machine co extrusion multi-layer production lines, which can process up to 7-9 layers of composite sheets for high barrier film(GWELL have invented the first 9-layer high baarrier film machine in China).

Production lines, such as high barrier EVOH multi-layer co extruded sheets. This model can process polyolefin materials such as PP, PS, PE, etc.

PET sheet, like other plastics, is closely related to molecular weight. The characteristic viscosity determines the molecular weight. The larger the typical thickness, the better the physical and chemical properties, but the poor fluidity makes it difficult to form. The lower the intrinsic viscosity, the worse its physical and chemical properties and insufficient impact strength.

PET sheet extrusion production line includes drying tower, extruder, screen changer, metering pump, T-die, three-roll calender, cooling-bracket ,winder. The production process is raw material drying - extrusion plasticization - extrusion molding - calendering - cooing - and winding products.

PP/PS sheet extrusion machine process:

1)Drying: Since water will hydrolyze and degrade PP/PS under high temperature conditions, resulting in a decrease in its characteristic adhesion, its physical properties, especially impact strength, will decrease with the decrease of molecular weight. Therefore, the PP/PS sheet extrusion line must dry the PP/PS before melting and extrusion to reduce the moisture content.

2) Extrusion molding: PP/PS is converted into polymer with obvious melting point after crystallization and drying. The polymer has a high molding temperature and a narrow temperature control range. The unmelted particles and melt are separated by a barrier screw dedicated to polyester, which helps maintain longer shear cycles and increases extruder yield.

3) T-die cooling forming: after flowing out of the melt T-die, directly into the three-roll calender for calendering and cooling, the three-roll calendering component upper, middle and lower three rollers, the center roller shaft is fixed, through the shaft up and down movement to adjust the roller gap, the three rollers should ensure the speed synchronization, the speed should be above the extrusion speed, the purpose is to offset the expansion of the sheet when the material leaves and weaken its internal stress, so that the horizontal grain disappears.

4) Haul-off unit and winding: The sheet comes out through calendering rollers and cooling rollers. Sufficiently cooled by the cooling bracket. Then into the traction device, the traction device is composed of active rubber rollers and passive rubber rollers, Gwell PP/PS sheet extrusion line can reach a maximum curling radius of 1.2 meters.

GWELL PP/PS sheet machine advantages

GWELL PP/PS Sheet Production Line have following advantages:

Adopting multiple co-extrusion machines to produce multi-layer co-extrusion composite PP and PS sheets, such as ABA, ABCBA, ABCDCBA and other multi-layer structures, widely used in thermo forming, printing, and other industries

Gold packaging, electronic trays, flocking, food, clothing, tools, toys, stationery pieces, decorative pieces, etc.

*Equipped with precision distributors, evenly layered, adjustable proportions for each layer, and digital precise control.

*The inclined horizontal pressing structure makes operation and maintenance more convenient.

*The roller has independent power and synchronous closed-loop control of linear speed and extruder speed.

*The entire machine adopts PLC control, achieving automatic control of parameter setting, data calculation, feedback, alarm and other functions.

*GWELL independently writes an electronic control operating system

Main uses of PP/PS sheets:

*PP/PS blister sheets

*PP/PS single-layer sheet, PP/PS co extruded dual color sheet, PP double-sided high transparency sheet, and other sheets used in the vacuum packaging industry.

*PP Stationery Piece

*PP transparent sheets, frosted sheets (coarse sand, fine sand), dual color sheets, and other sheets used in the stationery packaging industry.

Main applications of PP/PS sheet

Partner