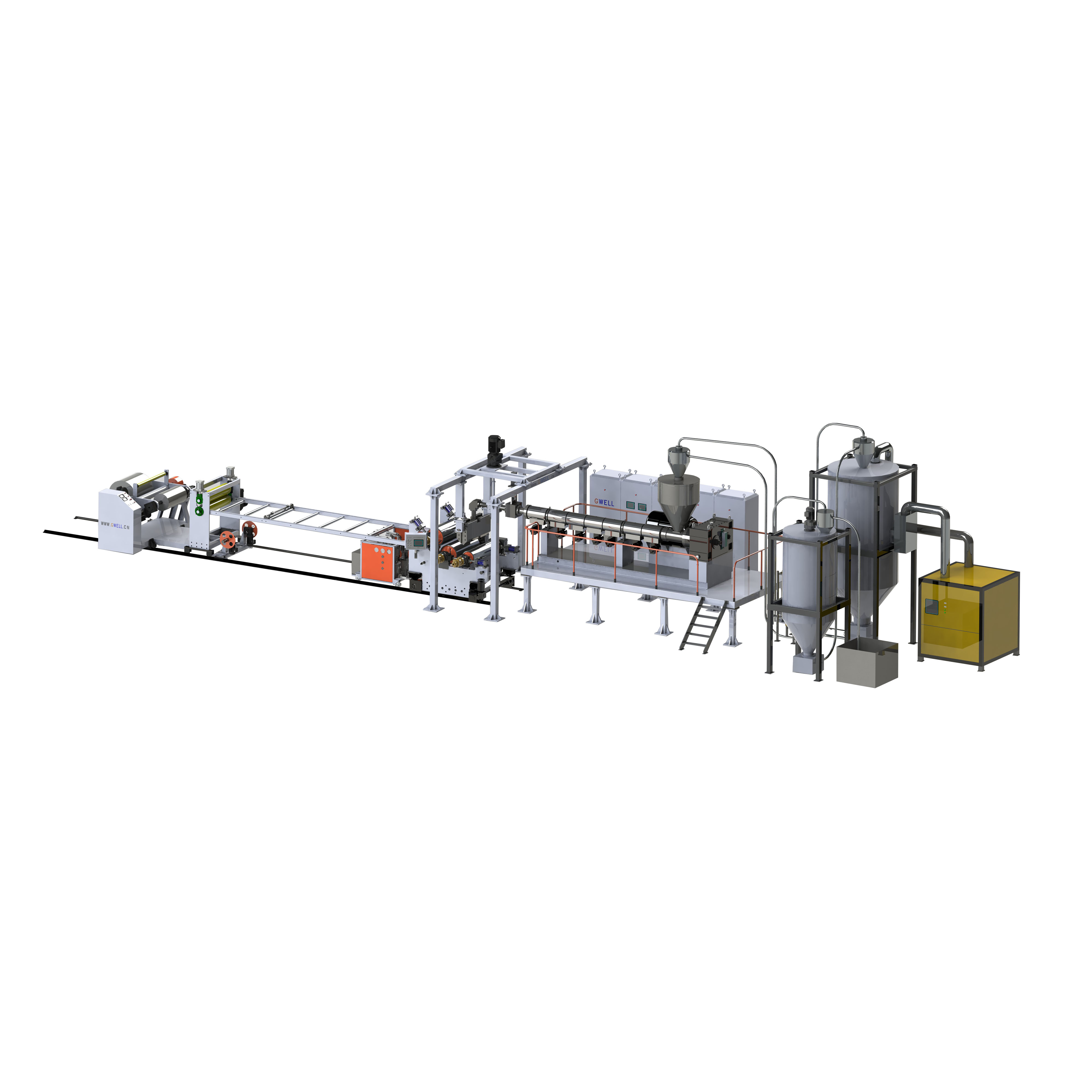

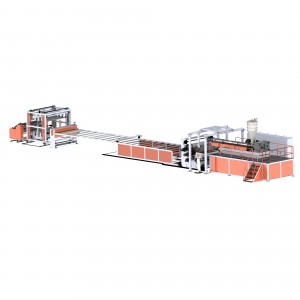

TPE Automotive Foot Mat Sheet Extrusion Line

Material Characteristics

1, Environmental protection: TPE sheet is a recyclable material, conducive to the recycling of resources.

2, Weatherability: TPE sheet can maintain stable performance in different environmental conditions, with good weather resistance and corrosion resistance.

3, Abrasion resistance: TPE sheet of high resistance and durability, can withstand long periods of use and wear and tear, to maintain its structure and performance stability.

4, High elasticity: TPE sheet has excellent resilience, can effectively relieve the impact and pressure, provide good cushioning and shock absorption effect. This characteristic makes TPE sheet has a significant advantage in shoe soles, footbeds, non-slip mats and other applications.

Wide range of applications

The products produced by TPE sheet production line are widely used in many fields due to their excellent physical properties, including but not limited to.

1, other fields: such as electronics, industrial products and other fields are also widely used.

2、Construction materials:Producing various types of sheets and films for interior decoration, wall decoration and other purposes.

3、Sports equipment:Manufacture of non-slip pads, cushioning pads and other components of sports equipment to enhance the safety and comfort of sports.

4、Automotive manufacturing: used to manufacture automotive foot mats, interior parts and other components to provide a comfortable ride and good shock absorption.

Production line composition and process

1, equipment composition: TPE sheet production line is mainly composed of extruder, mold, cooling system, traction machine, cutting machine and conveying system and other equipment. These equipments work together to ensure the production of sheet with stable and repeatable quality.

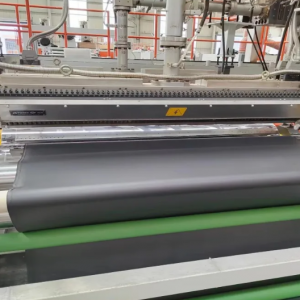

2、Production process:TPE raw material is heated and melted by the extruder, then extruded and molded into sheet through the die. The sheet is then rapidly cooled by the cooling system to fix its shape, and then pulled out by the traction machine and cut and transported.

Introduction to TPE Sheet Extrusion Line

Production Flexibility

1、Large freedom of design:TPE sheet production line can produce a variety of colors, shapes and specifications of the sheet to meet the needs of different areas. For example, it can be made into transparent, semi-transparent or opaque products, and the surface can also be made with characteristic patterns.

2, good processing performance: TPE sheet production line can use a variety of molding methods for mass production of complex products, high production efficiency, low cost.